Intellibox Counter

It is the most economical solution to control your fuel consumption with Intellibox Counter. Unique opportunities for construction and logistics companies

Introducing the Intellibox Counter

A cutting-edge fuel management solution revolutionizing the way you oversee and optimize fuel operations. From fuel tankers to unmetered fuel pumps, this system seamlessly integrates a fuel oil meter and automation, eliminating the need for an additional pump counter.

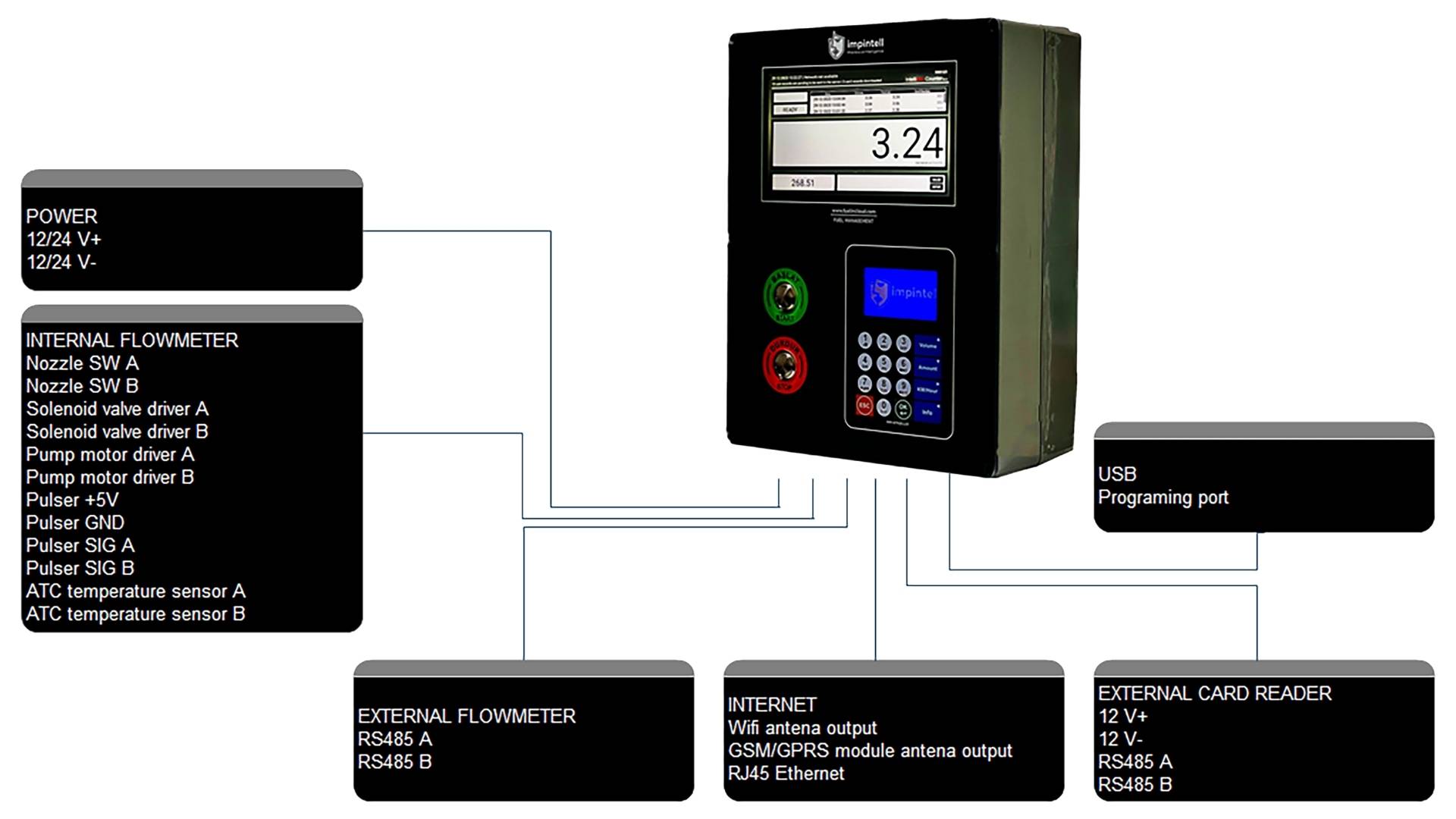

With a user-friendly keypad and RFID card authorization, presetting volumes is a breeze, ensuring precise control over fuel fillings. The Intellibox Counter operates online and offline, counting and transmitting fuel data to the cloud, making it a versatile choice for any setting. Its advanced features, including temperature sensors, solenoid valve outputs, and motor driver outputs, empower you to monitor and manage fuel passage efficiently.

Atlas Fuel Management facilitates centralized data collection and reporting, offering unparalleled insights for applications spanning multiple locations worldwide. Grant customized authorizations, set limits, and analyze consumption effortlessly. Elevate your fuel management strategy with Intellibox Counter – where innovation meets efficiency.

It is great solution for contructions sites

It is also good for logistics

Lets Take A Look At The Details

Best fuel management automation

It is the most economical solution to control your fuel consumption.

- It can be used in fuel tankers and trailers, fuel transfer sets and unmetered fuel pumps.

- Fuel oil meter and automation are integrated. There is no need for a fuel pump counter.

- It can works moothly with various types of pulsers. In addition to the temperature sensor, selenoid valve and motor driver outputs are also available.

- It keeps the fuel oil passage under control, when the flow rate drops too low, it can stop the pump motor or give a warning to the screen.

- Preset volume can be entered with the keypad on the card reader when the entered volume is reached, it automatically terminates the filling.

- It can work online and offline, counts your fuel and sends it to the cloud. For this, it is sufficient to be connected to the internet. In the absence of internet, it stores fillings records and sends them when connected to the internet.

- It is possible to collect data in a single centre, manage and report with Atlas Fuel Management in applications with multiple locations regardless of country and city.

- You can give different authorisations to RFID cards that you will define for users who will buy fuel.

- You can give a limit to any of them, you can allow any of them to buy fuel on limited days, and you can ensure that any of them are valid in certain locations or limited Intelliboxes.

- You can analyse the consumption by entering the km and working hour information of the vehicles receiving fuel through Intellibox.

| Operating voltage | 12/24V DC (750ma Nominal, Max. 2.5A with in-box heating) |

| Operating temprature Display | -25 ~ +70 °C |

| Computer Hardware | 7″ 1024 x 600 IPS, 800 nits (Wide viewing angle and sunlight readable) |

| 1.8 GHZ Quadcore main CPU, Embedded 3D GPU (OpenGL ES 1.1/2.0/3.2, OpenCL2.0 and Vulkan 1.1) | |

| 2G LPDDR4X/LPDDR4 and EMMC 32G Memory | |

| Embedded voltage, temperature and system clock supervisor with ARM Cortex MO | |

| USB, Ethernet Wifi, Bluetooth 4.1 port support is available depending on the application | |

| RFID reader and keyboard | 16-button alphanumeric keypad (Mileage, licence plate, etc. data can be entered) |

| ISO 14443 A/B MifareR 13.56 Mhz card reader | |

| STN 2.6″ Graphic display and buzzer | |

| Application ports voltage | Electrically galvanically/optically isolated RS485, RS232 and Current-Loop |

| An external dispenser with these ports according to the application requirement | |

| Can communicate with devices such as tank probe or printer | |

| Prevention | IP67 Sealed ABS box (4mm body thickness) and decorative plexiglass reinforced front surface |

| Input and output filters against EMC/ EMI problems | |

| Voltage against instantaneous voltage jumps similar to “Load Dump” for mobile vehicles protection is available | |

| Built-in fan for temperature spikes and heater for low temperatures | |

| Inside the box temperature and supply voltage are continuously measured to ensure the safety of the system internally reported | |

| Dimensions | 305 x 230 x 111 mm |

| Flowmeter features | Built-in flow meter with ARM Cortex M3 processor |

| 1 pulser, 2 relay outputs (selenoid valve and pump motor) and 1 ATC temperature sensor input | |

| IP67 protected industrial start and stop buttons | |

| Wide range of application-specific setting options are available with setup software | |

| Filling timeout, low flow, etc. detects errors and final sale in power outages can keep it |

System Concept